Some time ago I saw Turbokeu’s his mini power supply, and I thought “I can build a smaller one”. A month later I got an enclosure from a 12Vdc => 230Vac inverter (Thanks Jeroen!). This case was perfect for my mini psu. The volume off Turbokeu his supply is 1323cm³and mine will be 588cm³.

The circuit I used is based on an article Elektor published in march 98 (Called “Regelbare voeding” in Dutch). The displays are DPM125 witch I bought at an electronics flea market. The power supply delivers 3-24V at 1A. But this is only for short times because the case is used as heat sink.

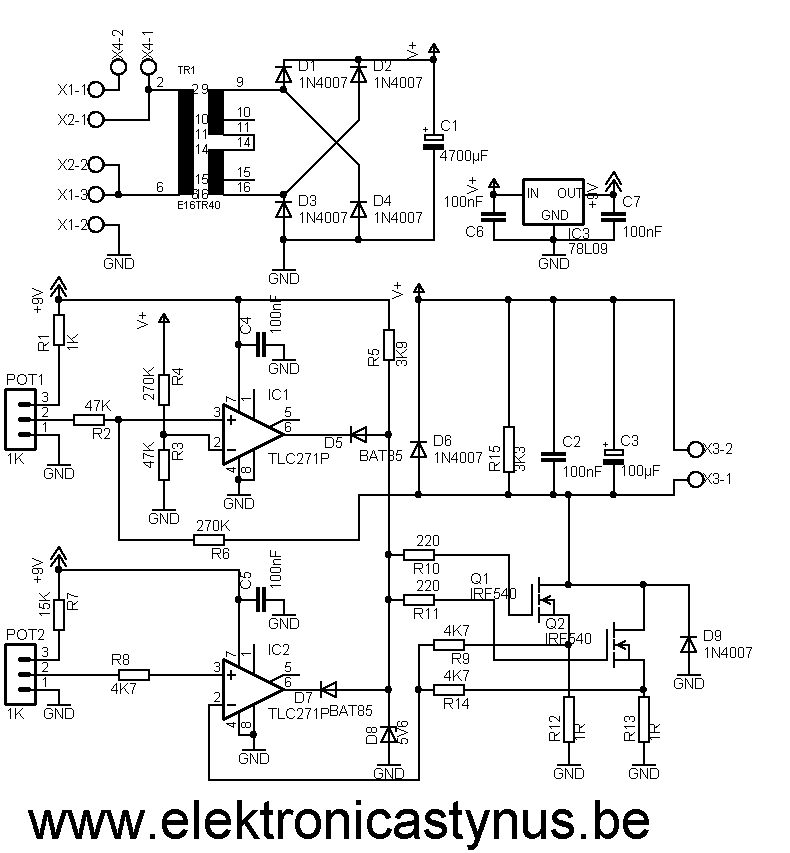

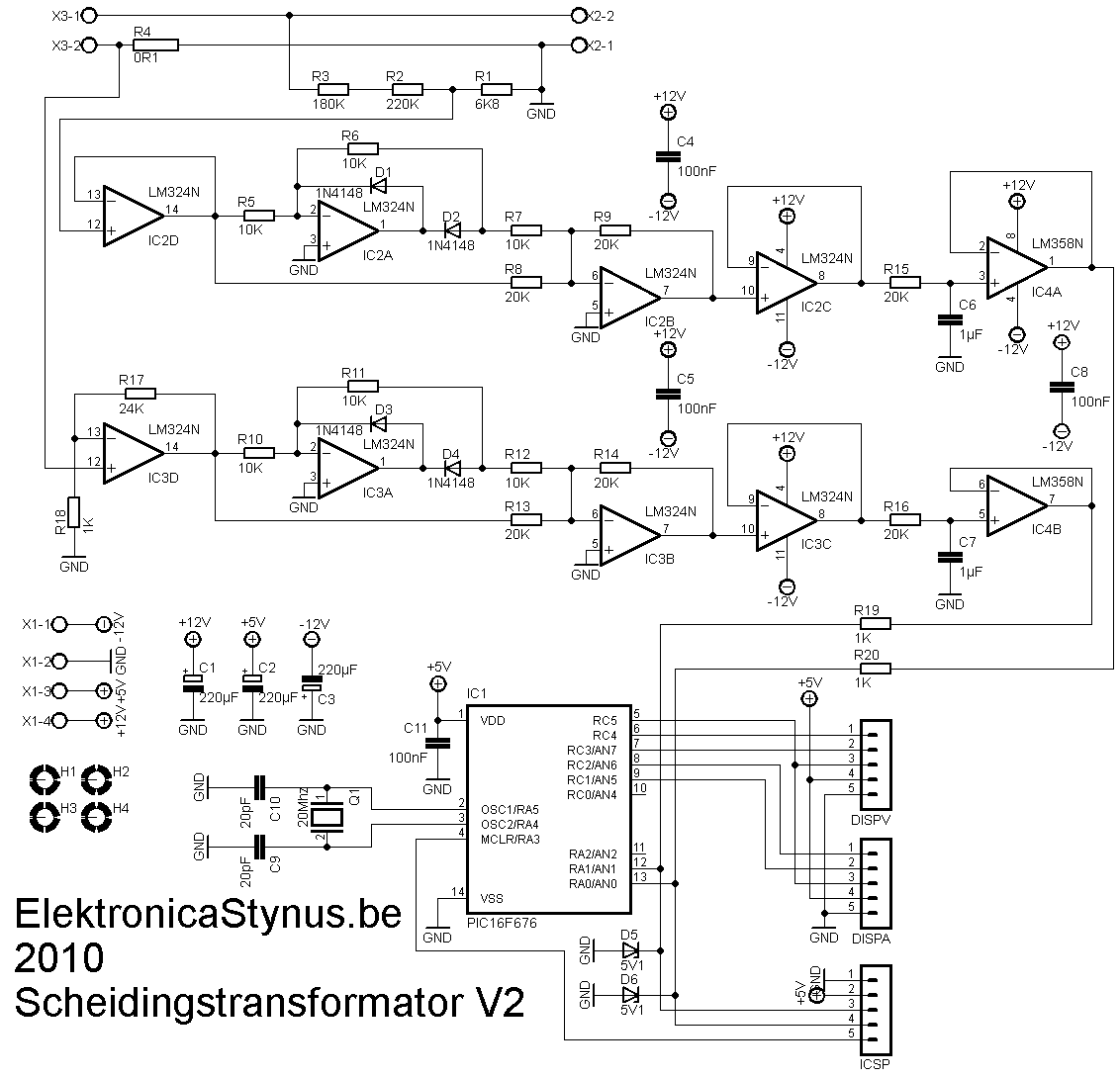

Circuit mainboard:

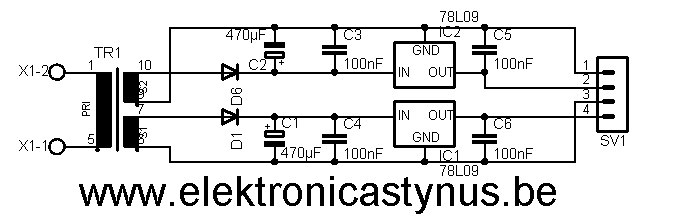

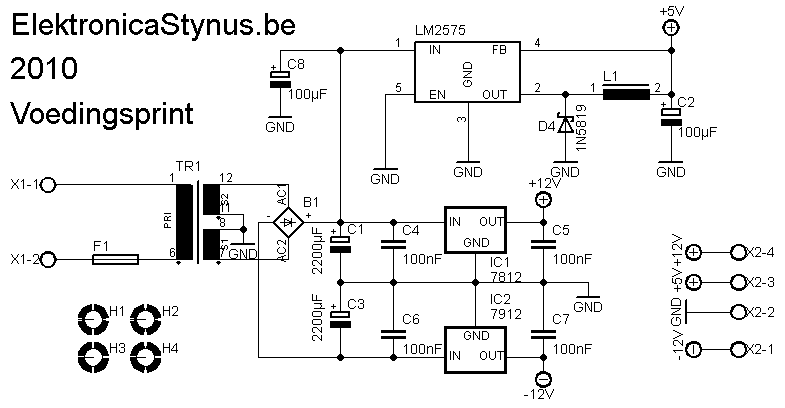

Circuit display supply:

Pcb mainboard:

Pcb display supply:

Part list (only from the mainboard):

| R1 | 1K 1206 |

| R2, R3 | 47K 0805 |

| R4, R6 | 270K 0805 |

| R5 | 3K9 0805 |

| R7 | 15K 0805 |

| R8, R9, R14 | 4K7 0805 |

| R10, R11 | 220R 0805 |

| R12, R13 | 1R 1W |

| R15 | 3K3 1W |

| C1 | 4700µF |

| C2, C4, C5, C6, C7 | 100nF 0805 |

| C3 | 100µF |

| D1, D2, D3, D4, D6, D9 | 1N4007 SMD DO214BA |

| D5, D7 | BAT85 |

| D8 | 5V6 zener |

| IC1, IC2 | TLC271 |

| IC3 | 78L09 |

| POT1, POT2 | 1K |

| Q1, Q2 | IRF540 |

| TR1 | transformer |

Pictures:

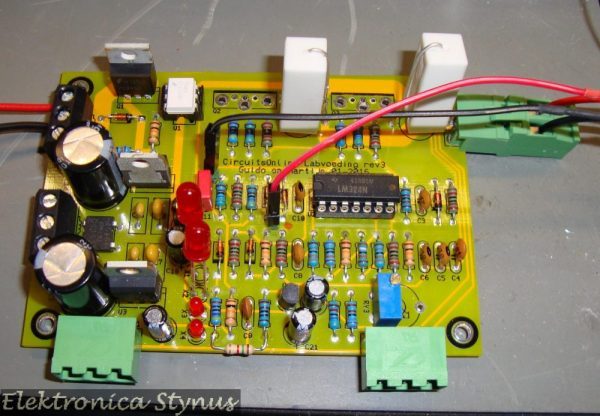

The top side of the mainboard:

Bottom side:

Bottom side of the display supply:

Top side:

Here you can see how much space is left![]() :

:

Closed:

2 pictures with my hand as size reference.