A few years ago I bought a second-hand Systron Donner HR 70-3AI power supply. This power supply works with a pre-regulation by “dimming” the transformer to limit the power dissipation. This works ok, but the psu has a rather big output capacitor (3300µF), which makes it unsuitable for testing circuits.

After a few months the psu broke down, and instead of fixing it I decided to upgrade it by adding a new lab power supply part. For this I used a board I got from an action on circuitsonline. The heat sinks are rather small and can not handle the 210W (70V x 3A), therefore I decided to reuse the pre-regulation and have it regulate about 10V above the output voltage. For this I designed an interface circuit.

Old power supply drive board / pre-regulation driver:

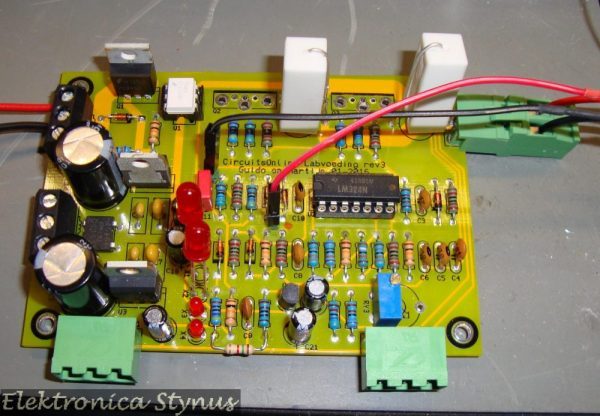

New lab power supply circuit:

Interface circuit rev 1:

Interface circuit rev 2:

Interface circuit rev 3:

Circuit diagram:

The boards mounted:

Other alterations that have been done on the power supply:

- The power transistors have been changed to transistors of the MJ11016 type

- An extra 2x9V AC PSU has been added

- The output capacitor has been changed from 3300µF to 150µF

- The potentiometers are changed to different values.

The new output cap:

Total overview:

On the outside nothing has been changed to the enclosure.