I have worked on this project again. The other 2 pcb’s are ready. Now it is time for the “hard work” (programming + testing).

Apr 29 2012

I have worked on this project again. The other 2 pcb’s are ready. Now it is time for the “hard work” (programming + testing).

Nov 12 2012

I had a lot of 10mF 6V capacitors where I didn’t had a use for. After putting them in a different place again, I decided to create a sort of spot welding machine with them. The inspiration comes from a elektor magazine where something similar is done.

The intention is that the amount of energy that is put in the capacitors is adjustable. Therefore the output power into the short-circuit will be adjustable. This is controlled by a microcontroller. I will also make a measurement on the output pins, so that sending the current to the output can be delayed after contact (to prevent sparks)

For adjusting the settings I have added a display and 3 buttons. For the display I chose an HP HDSP 2111 H5, this display is smaller than an LCD and therefore fits easily on the front panel, a disadvantage is that it can only display 8 characters.

The front panel layout I want to use:

The cap pcb:

In the enclosure:

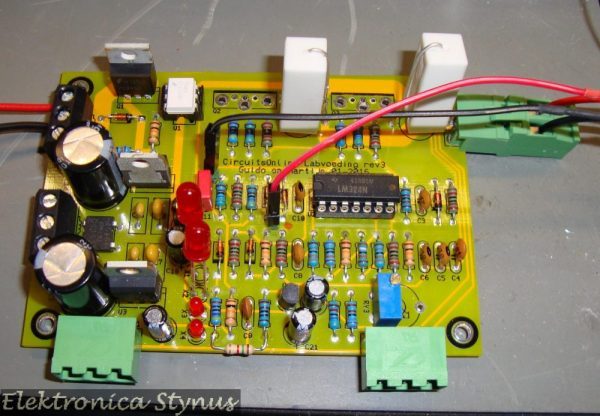

Control pcb:

The 2 pcb’s will be mounted on top of each other:

The front pcb is not made yet.

Circuits:

The capacitor pcb:

Control pcb:

Display pcb:

May 04 2013

After finishing the dummyload project, I remembered that this project uses the same display pcb’s. Therefore I could reuse most of the code. So I finished this project as well. The pic in the project is now a PIC16F1825 which operates at 32Mhz.

The code:

'**************************************************************** '* Name : Scheidingstransformator V2 * '* Author : Stijn Coenen ElektronicaStynus.be * '* Notice : Copyright (c) 2013 Stijn Coenen (Stynus) * '* : All Rights Reserved * '* Date : 01/05/2013 * '* Version : 1.3 * '* Notes : This code is provided to you as is, without * '* : warranty of any kind.Use at own risk!! * '**************************************************************** Device = 16F1825 Config1 FOSC_INTOSC, WDTE_OFF, PWRTE_ON, MCLRE_OFF, CP_OFF, CPD_OFF, BOREN_OFF, CLKOUTEN_OFF, IESO_ON, FCMEN_ON Config2 WRT_OFF, PLLEN_ON, STVREN_OFF, BORV_19, LVP_OFF Xtal = 8 '**************************************************************** 'EN: Declarations 'NL: Declaraties 'Displays Symbol Disp_klok = LATC.5 Symbol Spanning_Data = LATC.4 Symbol Spanning_Latch = LATC.3 Symbol Stroom_Data = LATC.2 Symbol Stroom_Latch = LATC.1 'EN: Measurement values 'NL: Meetwaardes Dim Spanning As Word Dim Stroom As Word Symbol N_Samp_U = 15 Dim GemU[N_Samp_U] As Word Symbol N_Samp_I = 15 Dim GemI[N_Samp_I] As Word 'EN: Display values 'NL: Display waardes Dim DispSpanning As Byte Dim DispStroom As Byte Dim DispArU[3] As Byte Dim DispArI[3] As Byte Dim IntCase As Byte Dim IntX As Byte Dim IntDisp As Byte Dim X As Byte Dim Temp As Byte 'EN: Settings AD converter 'NL: Instellingen AD converter Declare Adin_Res 10 Declare Adin_Tad FRC Declare Adin_Stime 250 'EN: Connections 7 segment displays on the 74HC595 pcb's 'NL: Aansluitingen 7 segment displays aan de 74HC595 op de printjes 'dPecgbfa Symbol Nul = %01001000 ' a '0 Symbol Een = %11101011 ' ##### '1 Symbol Twee = %01010010 ' # # '2 Symbol Drie = %01100010 ' f # g # b '3 Symbol Vier = %11100001 ' ##### '4 Symbol Vijf = %01100100 ' # # '5 Symbol Zes = %01000100 ' e # d # c '6 Symbol Zeven = %11101010 ' ##### '7 Symbol Acht = %01000000 '8 Symbol Negen = %01100000 '9 Symbol Uit = %11111111 'Out Symbol Streep = %11110111 'Bar 'EN: Connections of the transistors On the 74HC595 pcb's 'NL: Aansluitingen Transistoren aan de 74HC595 op de printjes Symbol disp1 = %00001100 Symbol disp2 = %00001010 Symbol disp3 = %00000110 'EN: Misc 'NL: Diverse Symbol TMR0IF = INTCON.2 'Tris registers TRISA = %11111111 TRISC = %00000000 All_Digital = true On_Hardware_Interrupt GoTo Interrupts '**************************************************************** Opstarten: 'EN: Set clock to 64 Mhz 'NL: klok instellen op 64 Mhz OSCCON = %11110010 Clear 'ram 'EN: Timer0 setup to drive the displays 'NL: Timer0 instellen om de displays aan te sturen OPTION_REG = %00000111 INTCON = %10100000 'EN: Settings AD converter 'NL: Instellingen AD converter ADCON1 = %10110000 GoTo Main '**************************************************************** Interrupts: Context Save If TMR0IF = 1 Then TMR0IF = 0 'Reset flag TMR0 = 230' 'Preloard timer 'EN: Loading data for the display that is driven this interrupt 'NL: Data inladen voor het display dat deze interrupt wordt aangestuurd DispSpanning = DispArU[IntCase] DispStroom = DispArI[IntCase] 'EN: Get the transistor settings and set the decimal point 'NL: Transistoren info uitlezen en de comma aanzetten Select IntCase Case 0 IntDisp = disp1 Case 1 IntDisp = disp2 Case 2 IntDisp = disp3 DispStroom.6 = 0 Case Else IntDisp = 255 IntCase = 0 EndSelect 'EN: Outputting transistors data 'NL: Transistor data inklokken For IntX = 0 To 7 Spanning_Data = IntDisp.7 Stroom_Data = IntDisp.7 Disp_klok = 1 IntDisp = IntDisp * 2 Disp_klok = 0 Next 'EN: Outputting display data 'NL: Display data inklokken For IntX = 0 To 7 Spanning_Data = DispSpanning.7 Stroom_Data = DispStroom.7 Disp_klok = 1 DispSpanning = DispSpanning << 1 DispStroom = DispStroom << 1 Disp_klok = 0 Next 'EN: Latch data to the outputs of the 74hc595 ic's 'NL: Data naar de uitgangen van de 74hc595 ic's latchen Spanning_Latch = 1 Stroom_Latch = 1 'EN: Set counter for next interrupt 'NL: Teller bijtellen voor volgende interrupt Inc IntCase If IntCase > 2 Then IntCase = 0 EndIf Spanning_Latch = 0 Stroom_Latch = 0 EndIf Context Restore Return '**************************************************************** Main: While 1 = 1 'EN: Voltage measurement 'NL: Spannings meting For X = (N_Samp_U - 1) To 1 Step -1 GemU[X] = GemU[X-1] Next Spanning = ADIn 0 Spanning = Spanning /10 Spanning = Spanning - 4.95 GemU[0] = Spanning * 3.25'3.03 Spanning = 0 For X = 0 To (N_Samp_U - 1) Spanning = Spanning + GemU[X] Next Spanning = Spanning / N_Samp_U 'EN: Current measurement 'NL: Stroom meting For X = (N_Samp_I - 1) To 1 Step -1 GemI[X] = GemI[X-1] Next Stroom = ADIn 1 Stroom = Stroom - 55 'Offset GemI[0] = Stroom /4.28 Stroom = 0 For X = 0 To (N_Samp_I - 1) Stroom = Stroom + GemI[X] Next Stroom = Stroom / N_Samp_I 'EN: Calculate value's for on the display 'NL: Meetwaardes naar display berekenen For X = 0 To 2 Temp = Dig Spanning, X DispArU[X] = LRead Cijfers + Temp Temp = Dig Stroom, X DispArI[X] = LRead Cijfers + Temp Next 'EN: Delay for slower display update 'NL: Wachten om het display niet te snel te updaten DelayMS 75 Wend '**************************************************************** Cijfers:- LData Nul, Een, Twee, Drie, Vier, Vijf, Zes, Zeven, Acht, Negen, Uit, Streep End

Files

Code file: Download

Hex file: Download

PCB file meter pcb: Download

May 04 2013

The electronics of the measuring pcb from this project is exactly the same as that from the safety transformer V2 project. Therefore I could now finish this design too.

The finished result:

May 04 2013

After a long time I decided to start again on this project. Quickly it became clear that there were still a few problems whit this project.

The first problem I encountered was that the transistors started to oscillate and draw to much base current when the voltage started to get to low. The oscillations turned out to be caused by the shutdown circuit I placed on the main pcb. After I removed this circuit the oscillations where gone. But there was still the problem of the too big base current in the transistors. This I solved by added 2 resistors to each step of the output stage.

R4 is added in this circuit. Also there needs to be a 150 Ohm 2W resistor placed between this pcb and the base of the 2N3055.

After these modifications it turned out that the power supply became a bit unstable. Therefore I replaced it by a 16V laptop charger. For the microcontroller and displays I added a voltage regulator pcb to create the required 5V.

The cooling fans need 12V, so I added a second voltage regulator pcb with a 7812 voltage regulator (mounted on the big heat sink).

When I was coding the current measurement I noticed another problem. The base current was also measured. To fix this I added a new pcb based on a ZXCT1086E5TA to measure the current trough the positive lead. This measurement however has the disadvantage to only work above 3V. This I “solved” by adding a few lines in the code which put — on the ampere display when the voltage gets too low.

To connect this pcb to the main pcb I had to mod the main pcb a bit:

New circuit:

To get a stable measurement, I take the mean value of a number of samples. For this code, the pic I originally designed into the the project, turned out to be too slow. Therefore I replaced it with a PIC16F25K22 (pin compatible). This pic operates at 64Mhz.

The code:

'**************************************************************** '* Name : Dummyload * '* Author : Stijn Coenen ElektronicaStynus.be * '* Notice : Copyright (c) 2013 Stijn Coenen (Stynus) * '* : All Rights Reserved * '* Date : 01/05/2013 * '* Version : 1.2 * '**************************************************************** Device = 18F25K22 Include "Config_Fuses_1_2.bas" Xtal = 16 '**************************************************************** 'EN: Declarations 'NL: Declaraties 'Displays Symbol Disp_klok = LATB.7 Symbol Temp_Data = LATB.2 Symbol Temp_Latch = LATB.1 Symbol Spanning_Data = LATB.4 Symbol Spanning_Latch = LATB.3 Symbol Stroom_Data = LATB.6 Symbol Stroom_Latch = LATB.5 'EN: Measurement values 'NL: Meetwaardes Dim Temperatuur As Word Dim Spanning As Word Dim Stroom As Dword Dim StroomFloat As Float Dim StroomPrecies As Bit Symbol N_Samp_T = 10 'Number of measuring samples; Aantal meetwaardes Dim GemT[N_Samp_T] As Word 'Array that contains the samples; Array die de meetwaardes bevat Symbol N_Samp_U = 15 Dim GemU[N_Samp_U] As Word Symbol N_Samp_I = 15 Dim GemI[N_Samp_I] As Word 'EN: Display values 'NL: Display waardes Dim DispTemp As Byte Dim DispSpanning As Byte Dim DispStroom As Byte Dim DispArT[3] As Byte Dim DispArU[3] As Byte Dim DispArI[3] As Byte Dim IntCase As Byte Dim IntX As Byte Dim IntDisp As Byte Dim X As Byte Dim Temp As Byte 'EN: Settings AD converter 'NL: Instellingen AD converter Declare Adin_Res 10 Declare Adin_Tad FRC Declare Adin_Stime 250 'EN: Connections 7 segment displays on the 74HC595 pcb's 'NL: Aansluitingen 7 segment displays aan de 74HC595 op de printjes 'dPecgbfa Symbol Nul = %01001000 ' a '0 Symbol Een = %11101011 ' ##### '1 Symbol Twee = %01010010 ' # # '2 Symbol Drie = %01100010 ' f # g # b '3 Symbol Vier = %11100001 ' ##### '4 Symbol Vijf = %01100100 ' # # '5 Symbol Zes = %01000100 ' e # d # c '6 Symbol Zeven = %11101010 ' ##### '7 Symbol Acht = %01000000 '8 Symbol Negen = %01100000 '9 Symbol Uit = %11111111 'Out Symbol Streep = %11110111 'Bar 'EN: Connections of the transistors On the 74HC595 pcb's 'NL: Aansluitingen Transistoren aan de 74HC595 op de printjes Symbol disp1 = %00001100 Symbol disp2 = %00001010 Symbol disp3 = %00000110 'EN: Misc 'NL: Diverse Symbol TMR0IF = INTCON.2 'Tris registers TRISA = %00111011 TRISB = %00000000 TRISC = %11111111 All_Digital = true On_Hardware_Interrupt GoTo Interrupts '**************************************************************** Opstarten: 'EN: Set clock to 64 Mhz 'NL: klok instellen op 64 Mhz OSCCON = %01110111 OSCCON2 = %11000111 Clear 'ram 'EN: Timer0 setup to drive the displays 'NL: Timer0 instellen om de displays aan te sturen T0CON = %11000111 INTCON = %10100000 INTCON2 = %00000100 INTCON3 = %00000000 IPR1 = %00000000 IPR2 = %00000000 IPR3 = %00000000 IPR4 = %00000000 IPR5 = %00000000 'EN: Settings AD converter 'NL: Instellingen AD converter ADCON1 = %00000000 ADCON2 = %10010111 GoTo Main '**************************************************************** Interrupts: Context Save If TMR0IF = 1 Then TMR0IF = 0 'Reset flag TMR0L = 230' 'Preloard timer 'EN: Loading data for the display that is driven this interrupt 'NL: Data inladen voor het display dat deze interrupt wordt aangestuurd DispTemp = DispArT[IntCase] DispSpanning = DispArU[IntCase] DispStroom = DispArI[IntCase] 'EN: Get the transistor settings and set the decimal point 'NL: Transistoren info uitlezen en de comma aanzetten Select IntCase Case 0 IntDisp = disp1 Case 1 IntDisp = disp2 DispTemp.6 = 0 DispSpanning.6 = 0 DispStroom.6 = StroomPrecies Case 2 IntDisp = disp3 DispStroom.6 = StroomPrecies + 1 Case Else IntDisp = 255 IntCase = 0 EndSelect 'EN: Outputting transistors data 'NL: Transistor data inklokken For IntX = 0 To 7 Temp_Data = IntDisp.7 Spanning_Data = IntDisp.7 Stroom_Data = IntDisp.7 Disp_klok = 1 IntDisp = IntDisp * 2 Disp_klok = 0 Next 'EN: Outputting display data 'NL: Display data inklokken For IntX = 0 To 7 Temp_Data = DispTemp.7 Spanning_Data = DispSpanning.7 Stroom_Data = DispStroom.7 Disp_klok = 1 DispTemp = DispTemp << 1 DispSpanning = DispSpanning << 1 DispStroom = DispStroom << 1 Disp_klok = 0 Next 'EN: Latch data to the outputs of the 74hc595 ic's 'NL: Data naar de uitgangen van de 74hc595 ic's latchen Temp_Latch = 1 Spanning_Latch = 1 Stroom_Latch = 1 'EN: Set counter for next interrupt 'NL: Teller bijtellen voor volgende interrupt Inc IntCase If IntCase > 2 Then IntCase = 0 EndIf Temp_Latch = 0 Spanning_Latch = 0 Stroom_Latch = 0 EndIf Context Restore Return '**************************************************************** Main: While 1 = 1 'EN: Temperature measurement 'NL: Temperatuur meting For X = (N_Samp_T - 1) To 1 Step -1 GemT[X] = GemT[X-1] Next Temperatuur = ADIn 1 Temperatuur = Temperatuur * 5 GemT[0] = Temperatuur / 9 Temperatuur = 0 For X = 0 To (N_Samp_T - 1) Temperatuur = Temperatuur + GemT[X] Next Temperatuur = Temperatuur / N_Samp_T 'EN: Voltage measurement 'NL: Spannings meting For X = (N_Samp_U - 1) To 1 Step -1 GemU[X] = GemU[X-1] Next Spanning = ADIn 0 GemU[0] = Spanning / 1.86 Spanning = 0 For X = 0 To (N_Samp_U - 1) Spanning = Spanning + GemU[X] Next Spanning = Spanning / N_Samp_U 'EN: Current measurement 'NL: Stroom meting For X = (N_Samp_I - 1) To 1 Step -1 GemI[X] = GemI[X-1] Next Stroom = ADIn 16 'EN: Setting the decimal point place 'NL: Plaats comma bepalen If Stroom > 500 Then 'X.XX StroomPrecies = 0 StroomFloat = Stroom * (5/1024) * 10 Else 'XX.X StroomPrecies = 1 StroomFloat = Stroom * (5/1024) * 100 EndIf StroomFloat = StroomFloat / 50 StroomFloat = StroomFloat / 0.005 GemI[0] = StroomFloat * 1.07 Stroom = 0 For X = 0 To (N_Samp_I - 1) Stroom = Stroom + GemI[X] Next Stroom = Stroom / N_Samp_I 'EN: Calculate value's for on the display 'NL: Meetwaardes naar display berekenen For X = 0 To 2 Temp = Dig Temperatuur, X DispArT[X] = LRead Cijfers + Temp Temp = Dig Spanning, X DispArU[X] = LRead Cijfers + Temp 'EN: The ZXCT1086E5TA does Not work below 3V, so display bars when this happens 'NL: De ZXCT1086E5TA werkt niet onder de 3V, dus als dit gebeurt streepjes weergeven If Spanning > 30 Then Temp = Dig Stroom, X DispArI[X] = LRead Cijfers + Temp Else DispArI[X] = Streep EndIf Next 'EN: Delay for slower display update 'NL: Wachten om het display niet te snel te updaten DelayMS 75 Wend '**************************************************************** Cijfers:- LData Nul, Een, Twee, Drie, Vier, Vijf, Zes, Zeven, Acht, Negen, Uit, Streep End

The dummyload working:

Files

Code file: Download

Hex file: Download

Sep 26 2014

I was thinking about making a resistor decade box, but I found the rotary switches that are used in these most of the time rather expensive and a bit old fashioned. That’s why I decided to use a rotary encoder and select the resistors with a microcontroller.

Now I only had to find a way to “make” the resistance. Switching resistors with transistors or mosfets gives a high switch resistance and can’t handle AC voltages. That’s why I opted to use relays. The currents that need to be switched are rather small, therefore a small relay is sufficient. The relay board is used 2 times with different resistor values.

Relay PCB:

Part list:

PCB low resistance:

| 3 | 1K | R22, R23, R24 |

| 1 | 1K8 | R26 |

| 3 | 1R | R1, R2, R3 |

| 1 | 1R8 | R5 |

| 1 | 2K2 | R25 |

| 1 | 2R2 | R4 |

| 1 | 3K3 | R28 |

| 1 | 3R3 | R7 |

| 1 | 4K7 | R27 |

| 1 | 4R7 | R6 |

| 3 | 10R | R8, R9, R10 |

| 1 | 18R | R12 |

| 1 | 22R | R11 |

| 1 | 33R | R14 |

| 1 | 47R | R13 |

| 3 | 100R | R15, R16, R17 |

| 1 | 180R | R19 |

| 1 | 220R | R18 |

| 1 | 330R | R21 |

| 1 | 470R | R20 |

| 2 | 100nF | C1, C2 |

| 2 | 74HCT595 | IC1, IC3 |

| 2 | ULN2803 | IC2, IC4 |

| 16 | TQ2-24V | K1, K2, K3, K4, K5, K6, K7, K8, K9, K10, K11, K12, K13, K14, K15, K16 |

PCB high resistance:

| 3 | 10K | R1, R2, R3 |

| 1 | 18K | R5 |

| 1 | 22K | R4 |

| 1 | 33K | R7 |

| 1 | 47K | R6 |

| 3 | 100K | R8, R9, R10 |

| 1 | 180K | R12 |

| 1 | 220K | R11 |

| 1 | 330K | R14 |

| 1 | 470K | R13 |

| 3 | 1M | R15, R16, R17 |

| 1 | 1M8 | R19 |

| 1 | 2M2 | R18 |

| 1 | 3M3 | R21 |

| 1 | 4M7 | R20 |

| 2 | 100nF | C1, C2 |

| 2 | 74HCT595 | IC1, IC3 |

| 2 | ULN2803 | IC2, IC4 |

| 12 | TQ2-24V | K1, K2, K3, K4, K5, K6, K7, K8, K9, K10, K11, K12 |

Control PCB:

Part list:

| 2 | 1uF | C3, C4 |

| 1 | 10K | R2 |

| 1 | 10K | R1 |

| 1 | 16F648A (Programmed) | IC1 |

| 2 | 100nF | C1, C2 |

| 1 | Push button | S1 |

| 1 | Rotary encoder | S1 |

| 1 | REG1117-5V | IC2 |

With frontpanel:

Power supply

This part is made on experiment board, therefore there are no circuit drawings available. The pcb exists of a 18V transformer; a rectifier and a capacitor.

Everything mounted in the enclosure:

Ready:

Code in the microcontroller:

Device = 16F648A Config FOSC_INTOSCIO, WDTE_OFF, PWRTE_ON, MCLRE_OFF, BOREN_OFF, LVP_OFF, CPD_OFF, CP_OFF All_Digital = true Xtal = 4 Declare PortB_Pullups On Declare LCD_DTPin PORTB.4 Declare LCD_ENPin PORTB.2 Declare LCD_RSPin PORTB.3 Declare LCD_Interface 4 Declare LCD_Lines 2 Symbol RotEncoderA = PORTB.1 Symbol RotEncoderB = PORTB.0 Symbol RotSwitch = PORTA.2 Symbol PushSwitch = PORTA.4 Dim PushSwitchBit As Bit TRISB = %00000011 TRISA = %01111100 OPTION_REG = %01000000 INTCON = %10010000 Symbol INTF = INTCON.1 Symbol klok = PORTA.0 Symbol Data_Pin = PORTA.7 Symbol ZetVast = PORTA.1 Dim DispWaarde[7] As Byte Dim SetWaarde[7] As Byte Dim DispTeller As Byte Dim CursorTeller As Byte Dim UitHex As Byte Dim UitDig As Byte Dim UitCount As Byte Dim ArrayTeller As Byte Dim Warning As Bit 'dim teller as byte On_Hardware_Interrupt GoTo IrInterrupt GoTo Init '**************************************************************** IrInterrupt: Context Save If INTF = 1 Then 'Flaggen resetten INTF = 0 If RotEncoderA = 1 Then 'Aftellen If DispWaarde[6 - DispTeller] > 0 Then Dec DispWaarde[6 - DispTeller] EndIf Else 'Optellen If DispWaarde[6 - DispTeller] < 9 Then Inc DispWaarde[6 - DispTeller] EndIf EndIf EndIf Context Restore '**************************************************************** Init: Cls UitDig = DispWaarde[3] UitHex = UitDig << 4 UitDig = DispWaarde[2] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitDig = DispWaarde[1] UitHex = UitDig << 4 UitDig = DispWaarde[0] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitHex = 0 UitDig = DispWaarde[6] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitDig = DispWaarde[5] UitHex = UitDig << 4 UitDig = DispWaarde[4] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] High ZetVast DelayUS 20 Low ZetVast '12345678 Print At 1, 1, "E-Stynus" Print At 2, 1, " 2014 " DelayMS 750 Cls Print At 1,1, "Set:" DispTeller = 0 'Ohm teken in lcd steken Print $FE,$40,$00,$0E,$11,$11,$11,$0A,$1B,$00 '**************************************************************** Main: While 1 = 1 'Relais aansturen bij rotary encoder button druk If RotSwitch = 0 Then For ArrayTeller = 0 To 6 SetWaarde[ArrayTeller] = DispWaarde[ArrayTeller] If SetWaarde[ArrayTeller] > 9 Then SetWaarde[ArrayTeller] = 0 DispWaarde[ArrayTeller] = 0 EndIf Next UitDig = DispWaarde[3] UitHex = UitDig << 4 UitDig = DispWaarde[2] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitDig = DispWaarde[1] UitHex = UitDig << 4 UitDig = DispWaarde[0] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitHex = 0 UitDig = DispWaarde[6] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] UitDig = DispWaarde[5] UitHex = UitDig << 4 UitDig = DispWaarde[4] UitHex = UitHex + UitDig UitHex = ~UitHex SHOut Data_Pin, klok, MsbFirst, [UitHex \ 8] High ZetVast DelayUS 20 Low ZetVast DelayMS 100 While RotSwitch = 0 DelayMS 100 Wend EndIf 'Warning teken Warning = 0 For ArrayTeller = 0 To 6 If DispWaarde[ArrayTeller] <> SetWaarde[ArrayTeller] Then Warning = 1 EndIf Next If Warning = 1 Then Print At 1, 8, "!" Else Print At 1, 8, " " EndIf 'Decade positie If PushSwitch = 0 And PushSwitchBit = 0 Then PushSwitchBit = 1 DelayMS 100 If DispTeller < 6 Then Inc DispTeller Else DispTeller = 0 EndIf EndIf If PushSwitch = 1 Then PushSwitchBit = 0 EndIf For ArrayTeller = 0 To 6 If DispWaarde[ArrayTeller] > 9 Then DispWaarde[ArrayTeller] = 0 EndIf Print At 2, 7 - ArrayTeller, Dec1 DispWaarde[ArrayTeller] Next Print At 2,8, 0 '(Print At 1,4, Dec DispTeller Print $FE, $0E 'Underline cursor on Print $FE, $C0 'Move cursor to beginning of second line CursorTeller = 0 While CursorTeller < DispTeller Print $FE, $14 'Move cursor right one position Inc CursorTeller Wend DelayMS 100 Wend End

Hex file: link

Oct 06 2014

After a few months of using this project it turned out that the solid state relays where not as reliable as first thought. One time the power relay stayed stuck close, but the resistors where not shorted by the other relay. This caused the resistors to get too hot (they are not calculated for continuous load).

The burned pcb:

After this I decided to build a new version of this pcb. This time with mechanical relays:

Circuit diagram:

PCB:

Picture:

The firmware in the microcontroller stays the same.

Oct 19 2014

A while ago I decided to convert my AMA-16 milling machine to cnc. For this machine I bought some stepper drivers to save the time of building them myself. I have mounted these drivers together with some power supplies and relays in a control box. Unfortunately I have not made many pictures during the build process.

Pictures:

Bottom side vent openings:

There are 3 ventilation openings on top. I protected these with air filters to keep out the dust.

The stepper motors are connected to the control box via speakon connectors:

Interface board:

On/off switch

Control circuit:

Sensor, power and control inputs:

I have mounted a touch-screen to the front of the control box.

More info will follow in a future update.

Jul 28 2017

Previous part of this project: Link

On the CircuitsOnline forum there was an action to buy power supply boards. At this action I bought 2 boards. When I was looking for an enclosure to use for this project I came across this old project and decided to use the enclosure for the new power supply.

For this design other auxiliary power supplies are needed than with the previous design. Therefore I made some new boards:

1x 2x9V AC psu to power the drive circuit and fan

2x 5V DC to power the V and A meter

1x board with big capacitors

Total overview with all boards:

After a few tests, it turned out that the heatsink became too hot. To solve this a fan was added.

This fan is controlled by temperature. This control is based on a MCP9701T sensor with a PIC16F527 micrcontroller.

The board of the fan controller:

Fan controller XC8 source code + hex download

The finished result:

Aug 05 2017

A few years ago I bought a second-hand Systron Donner HR 70-3AI power supply. This power supply works with a pre-regulation by “dimming” the transformer to limit the power dissipation. This works ok, but the psu has a rather big output capacitor (3300µF), which makes it unsuitable for testing circuits.

After a few months the psu broke down, and instead of fixing it I decided to upgrade it by adding a new lab power supply part. For this I used a board I got from an action on circuitsonline. The heat sinks are rather small and can not handle the 210W (70V x 3A), therefore I decided to reuse the pre-regulation and have it regulate about 10V above the output voltage. For this I designed an interface circuit.

Old power supply drive board / pre-regulation driver:

New lab power supply circuit:

Interface circuit rev 1:

Interface circuit rev 2:

Interface circuit rev 3:

Circuit diagram:

The boards mounted:

Other alterations that have been done on the power supply:

The new output cap:

Total overview:

On the outside nothing has been changed to the enclosure.