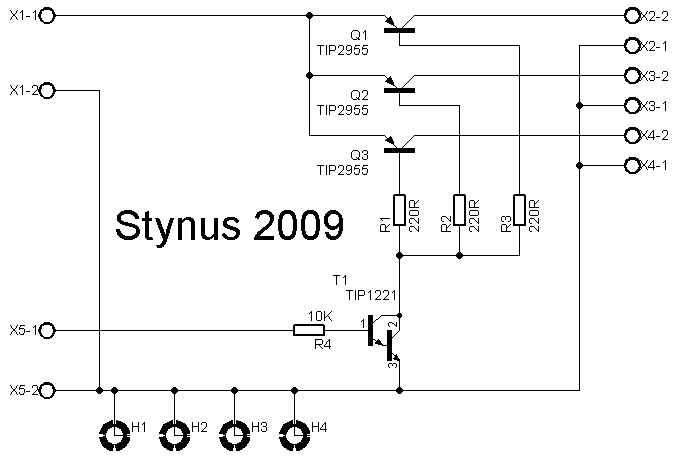

After a long time I restarted building on this power supply. I found a circuit where I’m going to base it on.

I’m not going to use this circuit exactly, but the main part I do.

In this design they used TIP142 transistors. In my version I used MJ2955 transistors. I was doubting if I would change the design or change the transistors on the heat sink. After a lot of thinking I opted for the second option. The new transistors are mounted directly on the heat sink, where the old ones used an bracket. This should provide a better cooling.

I didn’t trust the big capacitors I first planned to use any more. 1 of the 2 is so dehydrated that if you shake it you hear the inners rumbling louse. Instead of buying new big capacitors I opted to buy a few smaller ones. This is cheaper and gives a lower ESR. To mount them I made a pcb. Per side I use 3 capacitors of 3300µF 100V. That gives a capacity of 9900µF per side, this should be more than enough.

The next update will be the analog print. This design is 90% ready so it should not take too long (if no other project gets in between.)